Sheet & Heavy Metal Fabrication – Welding, Turning, Drilling

MELFAB Engineering

We have experience in the manufacture of special plant and equipment in the Chemical, Cable and Steel industries. Our capacity is as follows

Okuma CNC Lathe

- 340mm (13-1/4”) Dia. swing, 500mm (19-1/2”) between centers

- 420mm Dias. Swing, 750mm between centers, 4 axis capability

CNC Vertical Machining Centre

- 810mm (32”) x 580mm (22-3/4”) x 610mm (24”) Full 4-Axis contouring capability

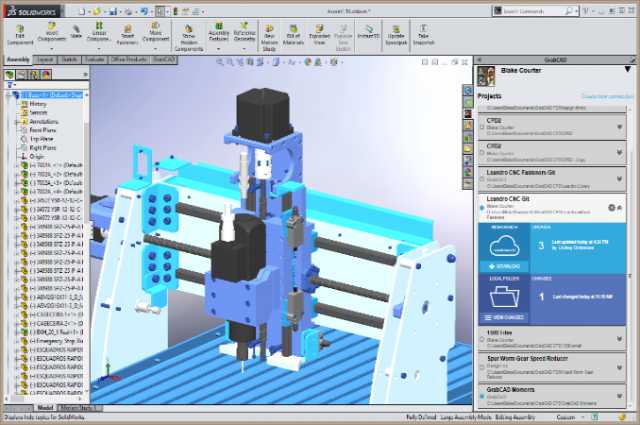

Solid CAM Integrated with Solid Works 2015

- 2D & 3D design system with tool path verification and post processor to program CNC Machine tools

Conventional Machinery

- Assorted Centre Lathes up to 840mm dia x 250l/g (remove bed gap) 640mmdia x 2500mm between centers

- Assorted Steel Milling Machine up to 1500mm (59”) x 500mm (19-1/2”) capacity

- Surface Grinding 630mm (25”) x 350mm (14”) capacity

REFINE Engineering

Refine Engineering is committed to providing the best manufacturing solutions to meeting your needs.

Refine Engineering excels at both long and short term research & design projects. From total package solutions to select parts or prototypes, we work extremely well with Engineers and Designers on a one-to-one or team basis. We understand not only the mechanical and manufacturing